The Rotor Slots Are Slightly Skewed In Squirrel Cage Induction Motor In Order To

Posted By admin On 26/07/22A squirrel-cage rotor is the rotating part of the common squirrel-cage induction motor.It consists of a cylinder of steel laminations, with aluminum or copper conductors embedded in its surface. In operation, the non-rotating stator winding is connected to an alternating current power source; the alternating current in the stator produces a rotating magnetic field.

Know about the most popular and almost unbreakable construction of Squirrel Cage Induction Motor. Know about the different winding slots, lamination of the stator and its construction. Also appreciate the rugged construction of squirrel cage rotor and know the spectacular reasons for the skewed arrangements of the rotor conductors. Know how a rotating magnetic field is produced. Know about the most popular and almost unbreakable construction of Squirrel Cage Induction Motor. Know about the different winding slots, lamination of the stator and its construction. Also appreciate the rugged construction of squirrel cage rotor and know the spectacular reasons for the skewed arrangements of the rotor conductors. Know how a rotating magnetic field is produced.

Types and Construction of Three Phase Induction Motor

Three phase induction motors are constructed into two major types:

1.Squirrel cage Induction Motors

2.Slip ring Induction Motors

1. Squirrel cage Induction Motors

(a) Stator Construction

The induction motor stator resembles the stator of a revolving field, three phase alternator. The stator or the stationary part consists of three phase winding held in place in the slots of a laminated steel core which is enclosed and supported by a cast iron or a steel frame as shown in Fig: 3.1(a).

The phase windings are placed 120 electrical degrees apart and may be connected in either star or delta externally, for which six leads are brought out to a terminal box mounted on the frame of the motor. When the stator is energized from a three phase voltage it will produce a rotating magnetic field in the stator core.

The Rotor Slots Are Slightly Skewed In Squirrel Cage Induction Motor In Order To *

(b) Rotor Construction

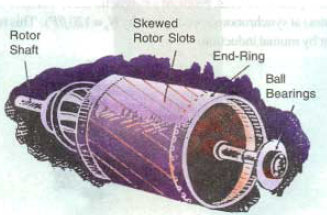

The rotor of the squirrel cage motor shown in Fig: 3.1(b) contains no windings. Instead it is a cylindrical core constructed of steel laminations with conductor bars mounted parallel to the shaft and embedded near the surface of the rotor core.

These conductor bars are short circuited by an end rings at both end of the rotor core. In large machines, these conductor bars and the end rings are made up of copper with the bars brazed or welded to the end rings shown in Fig: 3.1(b).In small machines the conductor bars and end rings are sometimes made of aluminium with the bars and rings cast in as part of the rotor core. Actually the entire construction (bars and end-rings) resembles a squirrel cage, from which the name is derived.

The rotor or rotating part is not connected electrically to the power supply but has voltage induced in it by transformer action from the stator. For this reason, the stator is sometimes called the primary and the rotor is referred to as the secondary of the motor since the motor operates on the principle of induction and as the construction of the rotor with the bars and end rings resembles a squirrel cage, the squirrel cage induction motor is used.

The rotor bars are not insulated from the rotor core because they are made of metals having less resistance than the core. The induced current will flow mainly in them. Also the rotor bars are usually not quite parallel to the rotor shaft but are mounted in a slightly skewed position. This feature tends to produce a more uniform rotor field and torque. Also it helps to reduce some of the internal magnetic noise when the motor is running.

(c) End Shields

The function of the two end shields is to support the rotor shaft. They are fitted with bearings and attached to the stator frame with the help of studs or bolts attention.

2. Slip ring Induction Motors

(a) Stator Construction

The construction of the slip ring induction motor is exactly similar to the construction of squirrel cage induction motor. There is no difference between squirrel cage and slip ring motors.

(b) Rotor Construction

The rotor of the slip ring induction motor is also cylindrical or constructed of lamination.

Squirrel cage motors have a rotor with short circuited bars whereas slip ring motors have wound rotors having 'three windings' each connected in star.

The winding is made of copper wire. The terminals of the rotor windings of the slip ring motors are brought out through slip rings which are in contact with stationary brushes as shown in Fig: 3.2.

THE ADVANTAGES OF THE SLIPRING MOTOR ARE

•It has susceptibility to speed control by regulating rotor resistance.

•High starting torque of 200 to 250% of full load value.

•Low starting current of the order of 250 to 350% of the full load current.

Hence slip ring motors are used where one or more of the above requirements are to be met.

3. Comparison of Squirrel Cage and Slip Ring Motor

You may have heard of the different parts making up your typical electric motor – including the squirrel-cage rotor bars. However, wrapping your mind around these rotor bars entail a different matter.

First and foremost, the squirrel-cage rotor got its name from its structural similarity to a squirrel cage. But its functionality has no connection or whatsoever with how a squirrel cage works.

In fact, the functions of a squirrel cage rotor in the motor are limitless. From preventing power losses to providing motion – it boosts the efficiency of a motor just like the other essential components within.

And all these are possible because of the skewing of squirrel-cage rotor bars. So, let’s move on and broaden your horizon about how this particular part works in your motor.

What are squirrel-cage rotor bars?

Among many other motor types, the squirrel-cage induction motor is one of the most sought after motors because of its simple and rugged construction – boosting properties like low-cost and low maintenance.

A standard squirrel-cage is made up of a cylinder of steel laminations in the core, together with proportionately spaced bars of aluminium or copper placed axially all around the outer edge, shorted at the ends permanently by the end rings.

With a few adjustments made here and there to the shape of the rotor bars, the speed-torque characteristics can be altered – to maximize low-speed torque or minimize the starting current for instance.

Reasons why squirrel-cage rotor bars are skewed

Unlike some of the other motors out there, the squirrel-cage rotor’s assembly is slightly different. The rotor bars are either skewed or slanted and they are done so for many various reasons:

Prevent cogging from occurring

If the rotor conductors are straight, in other words, not parallel to each other – the possibility of strong coupling or magnetic locking between the stator and rotor is pretty high. Even if the full voltage is being applied to the motor, there’s no way of starting it.

Which is why skewing comes in handy as it prevents this phenomenon – cogging – from happening.

Improved starting torque

When skewing is done, the length of the rotor bars increases while the cross-sectional area reduces. And as the resistance of the conductor is dependent on both of these factors – an increased resistance will lead to an improved power factor of the rotor circuit. In turn, increase the starting torque of the motor.

Prevent crawling

When the induction motor runs at extremely low speed, it is known as crawling. And this happens as a result of harmonics, introducing oscillations in torque. Once the rotors are skewed, this negative outcome is avoided as they reduce the tooth harmonics effectively.

A reduction in magnetic hum

Skewed or slanted motors cause a drop in magnetic hum. When this happens, the chances of rotor locking decreases and the motor runs much quieter.

Signs of squirrel-cage rotor bars failure

Unfortunately, a failure in the squirrel-cage rotor bar is bound to happen. And at times, it would mean that its time for an electric motor overhauling to figure out what is the main reason behind the failure.

While it is an event that is unavoidable, there are still ways to restore the motor back to its original state or even prevent the malfunction from occurring.

Below, are some signs you should look out for to spot a failure:

Broken bars: Usually, the breaks happen within the slot section, where the end ring meets the bar, and when the bar goes into the core.

Excessive starting: A decrease in motor performance will happen sooner or later due to the number of uses and starts.

Ring rotors: Due to a welding failure, breaks within the rotor winding occur – resulting it to slip from its original position.

Long start-up time: Large inertial loads are usually the source for this problem, causing unnecessary strain on the motor – resulting in permanent damage.

Bearing failures: When an already taut belt is overloaded – bearing failure happens. Besides the mentioned issue, other reasons also include stresses and axial impacts.

In order for you to understand what is wrong with your motor, or how to improve it – you need to know each and every part of the equipment completely. While carbon brushes and commutators do play a part – so does the squirrel-cage rotor.

The Rotor Slots Are Slightly Skewed In Squirrel Cage Induction Motor In Order To Mcq

Know how it works and you’ll understand when it’s time to do an electric motor repair. But at the end of the day, these are just the basics of the squirrel-rotor bar. When none of the above-mentioned signs is spotted, it would be good to call for an electric motor service to find out the issue with your equipment.